2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

2020/10/21

From October 20th to 21st, the 2020 China Titanium, Zirconium and Hafnium Annual Conference and Summit Forum with the theme of “Innovation and Leading to Build a New Development in the Titanium, Zirconium and Hafnium Industry” was held in Beijing. More than 300 industry experts and entrepreneurs focused on the industry Hot spots and difficulties will further promote the steady and healthy development of the titanium, zirconium and hafnium industry.

Ma Rui, deputy general manager of Tiancheng Aviation Materials, made a keynote speech

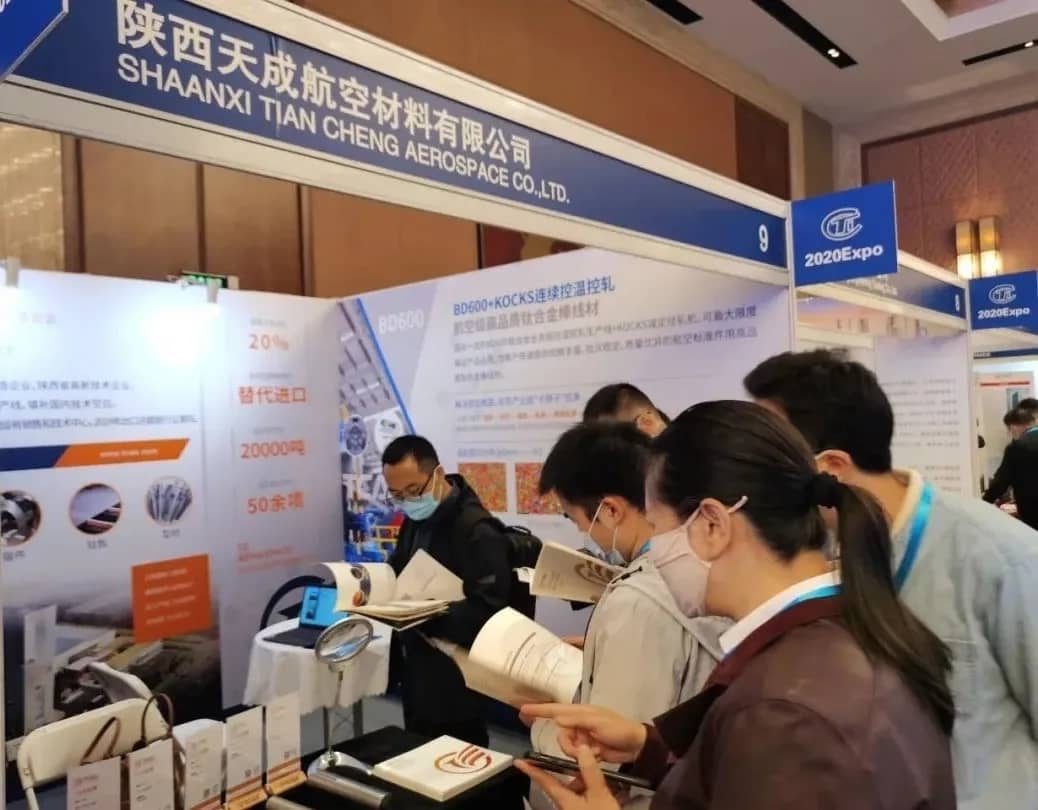

Tiancheng Aviation Materials exhibits the latest rod and wire products

At the meeting, Ma Rui, deputy general manager of Tiancheng Aviation Materials, made a theme report on “Leading the 4.0 New Era of Titanium Alloy Development”. Starting from solving specific application requirements for aviation fasteners, engine blades, and aircraft structural parts, Tiancheng Airlines introduced in detail. The latest research and development products of materials are highly recognized by on-site experts. The 2020 China Titanium, Zirconium and Hafnium New Products and New Technology Exhibition was held concurrently with the conference. Tiancheng Aviation Materials brought the latest titanium alloy rods and wire products to a grand appearance and received widespread attention.

#Replacement of imports, manufacturing to serve the country

High-quality rod and wire to solve the domestic demand for aviation fastener raw materials

At present, domestic titanium alloy rods and wires for aviation fasteners mainly rely on imports, and the localization of raw materials is imminent. The titanium alloy full-process temperature-controlled rolling production line independently developed and designed by Tiancheng Aviation Materials can produce φ1.0mm-15.0mm titanium alloy wire coils, with a single coil weight up to 200kg, and has excellent quality functions The coating and precision exceed H6, and it has good processing performance, which solves the current industry pain points to the greatest extent and gradually realizes the substitution of imported materials.

High quality titanium alloy rod and wire

#Independent innovation, first-class benchmarking

Rods for ultra-fine crystal blades, empowering the development of the aero engine industry

(Ultra) fine-grained blades are already the standard equipment in the R&D and manufacturing of world-class engines, and there is little domestic demand. Tiancheng Aviation Materials’ new product ultra-fine-grained blade rods empower China’s aviation engine industry upgrade from the material layer, providing more domestic engines may. The most important mechanical property that determines the service performance and life of the engine blade is the high cycle fatigue performance. Tiancheng Aviation Material’s full-process temperature-controlled rolling production line can realize the internal grain refinement of the bar, reduce the degree of material micro-texture, and increase the high cycle of titanium alloy Fatigue crack initiation resistance, thereby significantly improving the strength and life of the blade.

#Rolling instead of forging, combining forging and rolling

Improve the consistency of large-size titanium rods and escort the quality of aviation structural parts

At present, domestic medium and large size bars are mainly produced by free forging. Forged bars have high versatility and forging penetration, but at the same time process stability and repeatability are poor, and the length and unit weight restrictions are large, and the product consistency is poor The problem has always plagued users in the industry. Tiancheng Aviation Materials adopts forging and rolling combined method, equipped with 8000T fast forging machine and self-developed and self-designed full-process temperature-controlled rolling production line, which can produce medium and large-sized bars with stable quality and consistent performance, meeting domestic aviation structural parts and The quality and efficiency requirements of raw materials such as engine disc and ring parts have narrowed the technological gap between China and foreign countries.

Full-process temperature-controlled rolling production line of Tiancheng Aviation Materials

One step at a time, love and focus have enabled Tiancheng Aviation Materials to always focus on the pain points of user development, and to advance the titanium industry to a more high-end and smarter road. In 2020, the company’s newly built aerospace-grade titanium alloy rod and wire production line was officially put into operation. The intelligent, unmanned, and fully automatic production line with an investment of 1.28 billion has begun to scale, which can provide sufficient and competitive raw material support for the development of China’s aviation industry. . Tiancheng Aviation Materials will continue to seize the technological change window, keep a close eye on customer market needs, make full use of the information and digital development wave, continuously upgrade factories, optimize processes, and make refined products, leading the development of titanium alloys into a new era of 4.0.